Direct Metal Laser Sintering (DMLS)

Description

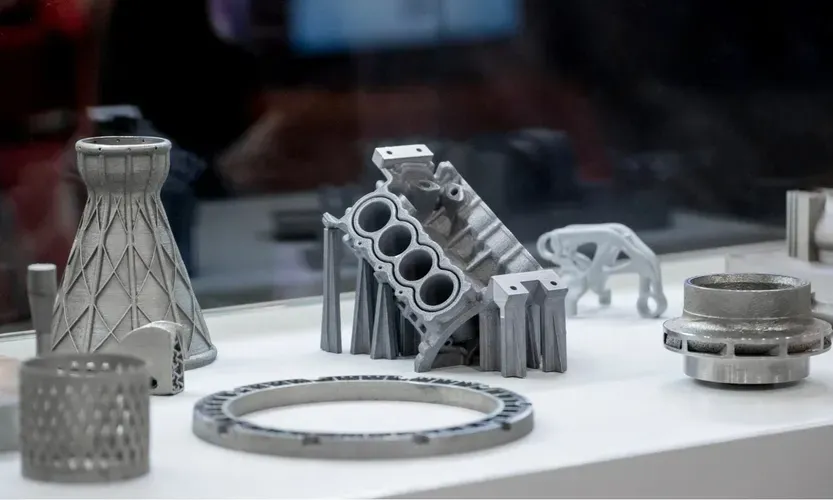

DMLS is an advanced powdered bed fusion (PBF) technique where a re-coater blade or roller evenly distributes powdered metal across a substrate. A high-precision laser then selectively melts the powder layer by layer to build up the desired part. This method is highly regarded in the automotive and aerospace industries for producing high-performance metal components with exceptional precision and strength.

Materials Available

- Aluminium Alloy (AlSiMg)

- Aluminum

- CO-CR Alloy (MPT)

- Chromium Bronze (QCR 1)

- Cobalt Chrome

- Copper

- Die Steel (MS1)

- Inconel

- Maraging Steel

- NI Base Superalloy (In 718)

- SS316

- SS316 L

- Titanium

- Titanium Alloy (TC4)

Technical Details

- Mechanical Properties: High strength and durability comparable to traditionally manufactured metal parts.

- Surface Finish: Rough; typically requires post-processing for smoothness.

- Dimensional Accuracy: High, within ±0.1mm.

- Max Build Size: Typically up to 250 x 250 x 325mm.

- Speed of Production: Moderate to slow.

Advantages

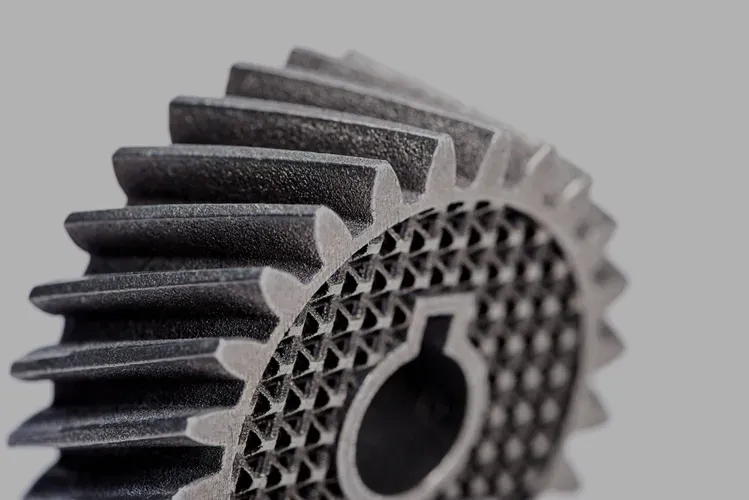

- Can be used to print parts with lattice structures and topology optimized designs, which can reduce weight while maintaining strength.

- Does not require support structures, which allows for more complex geometries and dimensional accuracy.

- Excellent material properties suitable for functional parts.

Ready to Start Your Project?

Our team of experts will help you choose the right technology and materials.