An Evolution In

Manufacturing

From rapid prototyping to production-ready parts, we offer comprehensive

manufacturing services powered by cutting-edge technology.

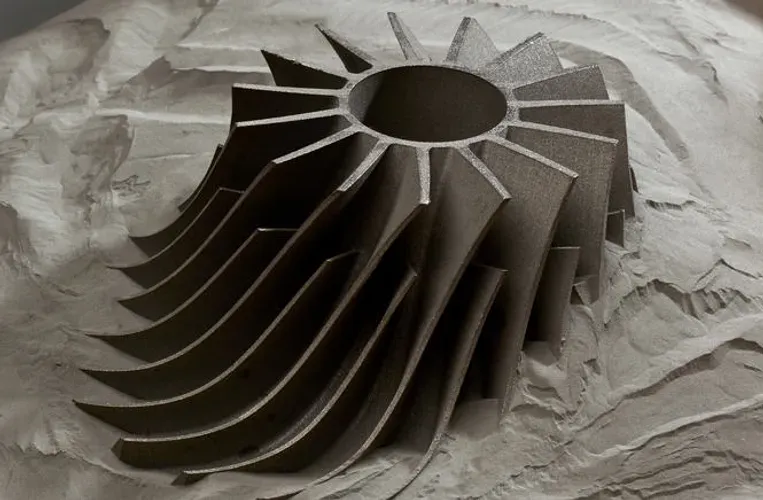

Direct Metal Laser Sintering (DMLS)

DMLS is an advanced powdered bed fusion (PBF) technique where a re-coater blade or roller evenly distributes powdered metal across a substrate. A high-precision laser then selectively melts the powder layer by layer to build up the desired part. This method is highly regarded in the automotive and aerospace industries for producing high-performance metal components with exceptional precision and strength.

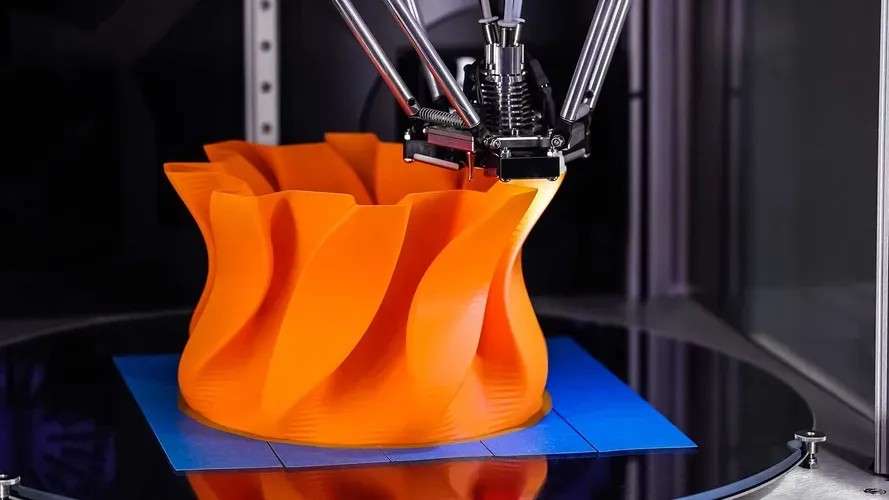

Fused Deposition Modeling (FDM)

FDM is a widely used 3D printing technique that employs a heated extruder to deposit thermoplastic filament layer by layer, gradually building up a solid object. Known for its versatility and affordability, FDM is one of the most popular 3D printing methods available. Its compatibility with a diverse range of filaments makes it suitable for a broad array of applications, from prototypes to functional parts.

Vacuum Casting

Vacuum Casting is used to produce high-quality parts with detailed and accurate features, often mimicking the properties of injection-molded parts.

Selective Laser Sintering (SLS)

SLS is a cutting-edge 3D printing technique that uses polymer powders. In this process, a thin layer of powdered material is evenly spread across the build plate. A laser beam then selectively melts the powder according to the design, layer by layer. As each layer is completed, the build plate descends, and a new layer of powder is applied, with the process repeating until the part is fully formed. The surrounding powder acts as a natural support structure, eliminating the need for additional supports. This method is particularly well-suited for producing intricate, high-strength components with exceptional durability.

Digital Light Processing (DLP)

DLP is an advanced 3D printing technology that employs a digital light projector to cure resin layer by layer. This technique delivers outstanding dimensional accuracy, making it ideal for applications requiring precise tolerances, such as in the dental and jewelry industries. The high resolution and detail achieved with DLP ensure that each part meets stringent quality standards.

Stereolithography (SLA)

Stereolithography (SLA), also known as vat photopolymerization or resin 3D printing, is an advanced additive manufacturing process that uses a light source to cure liquid resin into solid plastic. SLA stands out for its exceptional speed, highest resolution, and accuracy, delivering the sharpest details and smoothest surface finishes among 3D printing technologies. Its unparalleled precision makes SLA particularly well-suited for medical and dental applications, as well as a wide range of general additive manufacturing needs.

HP Multi Jet Fusion (MJF)

MJF 3D printing is a Powder Bed Fusion (PBF) technology that uses a heat source to fuse thermoplastic powder particles—typically nylon or TPU—within a build chamber. This process combines infrared energy with a fusing agent to create each layer of the part. MJF is renowned for producing robust components with moderate temperature resistance, making it ideal for applications such as engine housings, bellows, baffles, and jigs and fixtures.

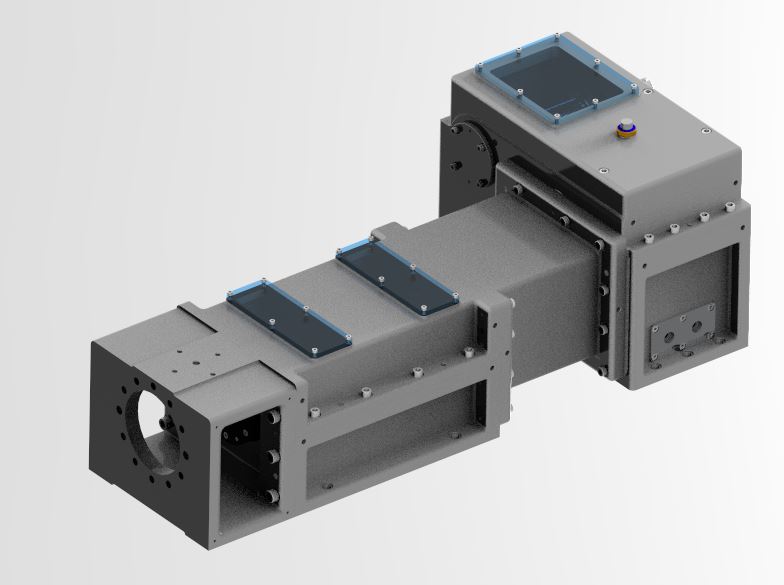

Product Design and Development

Turn your vision into reality with Instrumus's premier Product Design Service, developed in partnership with iMAC, leveraging their expertise in design and rapid prototyping. At the heart of successful product development lies a precise and expertly crafted CAD design, serving as the blueprint for reliability and innovation. Our service empowers you to simulate, test, and refine your ideas across diverse environments, ensuring every detail aligns with your goals. Instrumus goes beyond traditional design solutions by connecting you with a network of top-tier design experts who bring technical excellence and creative insight to your projects. Whether you're developing a groundbreaking product or refining an existing concept, we are committed to delivering designs that exceed expectations. From initial sketches to detailed prototypes, Instrumus ensures your concepts are brought to life with unmatched quality, efficiency, and attention to detail.

MultiJet Printing (MJP)

MultiJet Printing (MJP), also known as Wax Jet Printing, is a high-resolution additive manufacturing process that uses photopolymer or wax-like materials. It operates by jetting microscopic droplets of material layer by layer, which are then cured using UV light. This technology is excellent for producing detailed prototypes, casting patterns, and tooling masters with exceptional surface quality and accuracy.

Ready to Start Your Project?

Our team of experts will help you choose the right technology and materials.