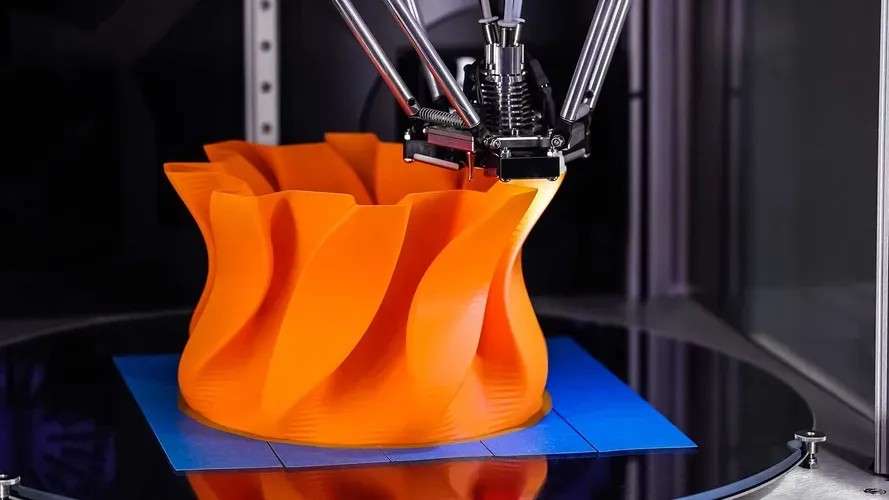

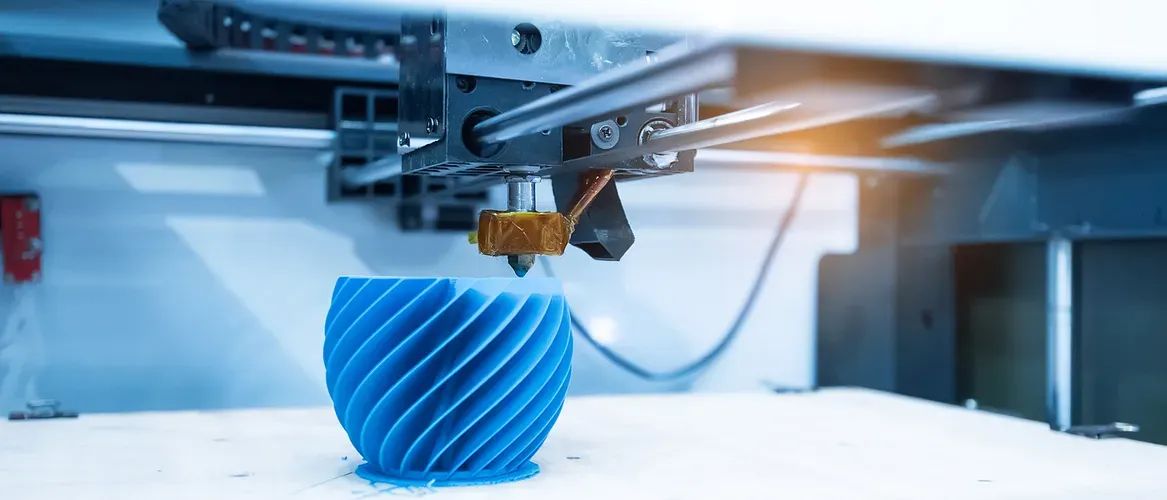

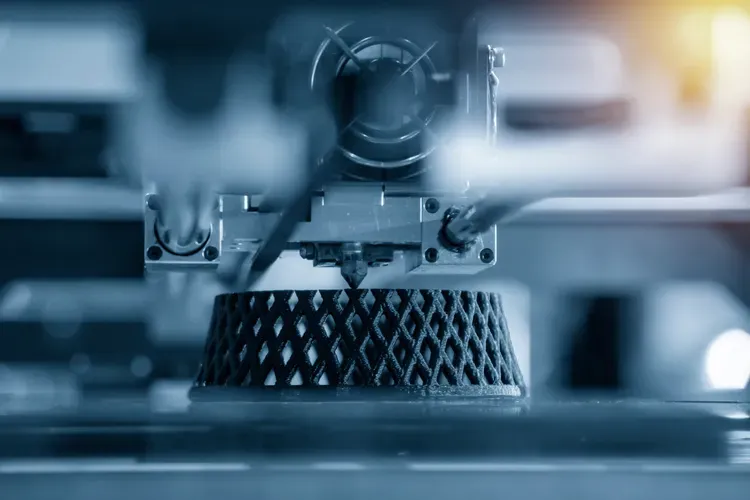

Fused Deposition Modeling (FDM)

Description

FDM is a widely used 3D printing technique that employs a heated extruder to deposit thermoplastic filament layer by layer, gradually building up a solid object. Known for its versatility and affordability, FDM is one of the most popular 3D printing methods available. Its compatibility with a diverse range of filaments makes it suitable for a broad array of applications, from prototypes to functional parts.

Materials Available

- High-Impact Polystyrene (HIPS)

- Acrylonitrile Butadiene Styrene (ABS)

- Carbon Fiber (CF)

- Carbon Filled Nylon

- Flex PLA (Polylactic acid)

- Glass Filled Nylon

- Nylon

- PLA (Polylactic acid)

- Polycarbonate (PC)

- Polyethylene Terephthalate Glycol-Modified (PETG)

- TPE (thermoplastic elastomer)

- Thermoplastic Polyurethane (TPU)

- PC + ABS

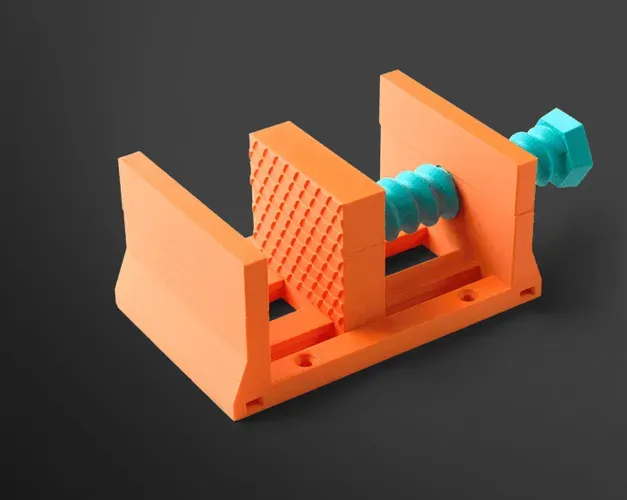

Technical Details

- Mechanical Properties: Varies with material.

- Surface Finish: Visible layer lines, may require post-processing.

- Dimensional Accuracy: Moderate to high, within ±0.2mm.

- Speed of Production: Moderate.

Advantages

- Cost-effective and versatile.

- Wide range of materials.

Ready to Start Your Project?

Our team of experts will help you choose the right technology and materials.