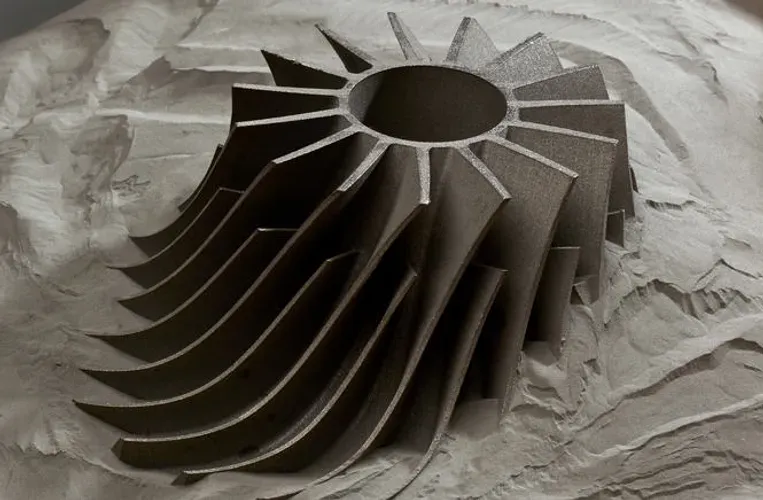

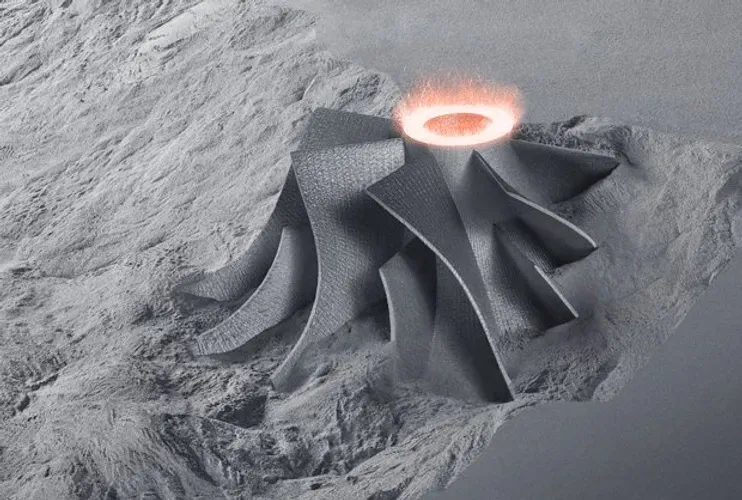

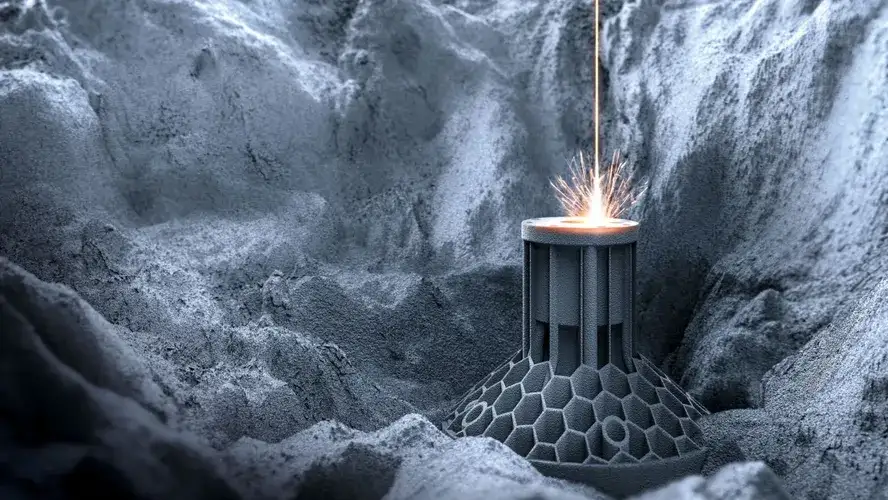

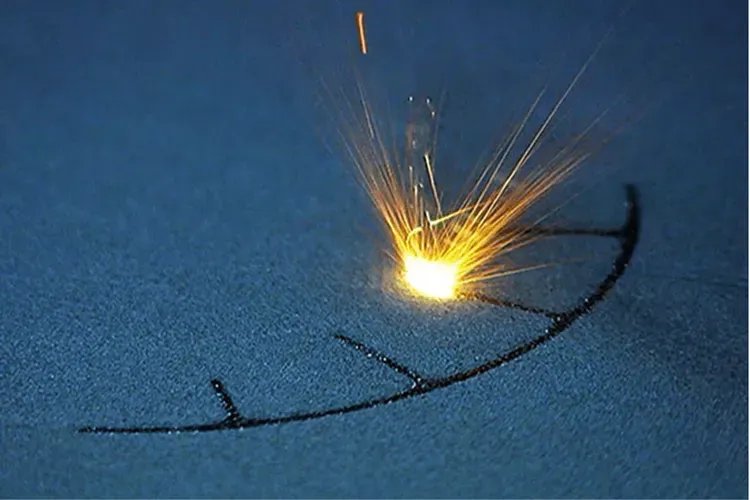

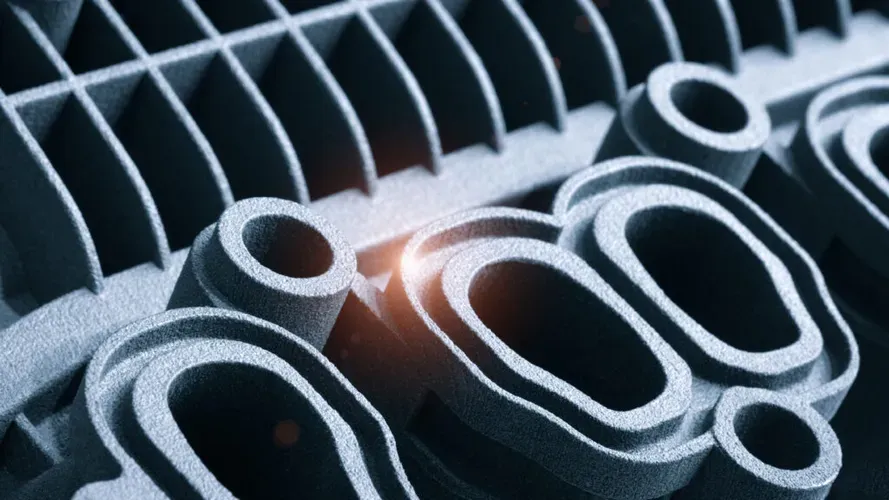

Selective Laser Sintering (SLS)

Description

SLS is a cutting-edge 3D printing technique that uses polymer powders. In this process, a thin layer of powdered material is evenly spread across the build plate. A laser beam then selectively melts the powder according to the design, layer by layer. As each layer is completed, the build plate descends, and a new layer of powder is applied, with the process repeating until the part is fully formed. The surrounding powder acts as a natural support structure, eliminating the need for additional supports. This method is particularly well-suited for producing intricate, high-strength components with exceptional durability.

Materials Available

- Semi-crystalline polymer polyamide 12 (PA12)

- Polyamide 12 Nylon (Nylon PA12)

- PA12+Glass Filled

- PA22

- PA6

- Nylon PA2200

- Nylon PA3200

Technical Details

- Mechanical Properties: Excellent strength and durability.

- Surface Finish: Slightly rough, may require post-processing.

- Dimensional Accuracy: High, typically within ±0.1mm.

- Max Build Size: 700 x 380 x 580mm.

- Speed of Production: Moderate to fast.

Advantages

- Capable of complex geometries.

- Lightweight and durable parts.

Ready to Start Your Project?

Our team of experts will help you choose the right technology and materials.